Functional Test Fixtures

Functional Test Fixture is a final test done after a product is manufactured to check its practicality and detect any malfunctions. Therefore, functional test fixtures refer to devices that are used to assess pieces of a system or software to validate their functionality. Functional testing can be done on the basis of the business perspectives and requirements to be met.

Custom Functional test fixtures can be utilized to evaluate digital, hybrid and even analog boards. A specification document is covered in order to verify that specific requirements of the product are met and also what the user expects of it. The ideal beneficiaries of Custom functional test fixtures are mainly those who deal with manufacturing businesses.

Considering our technology today, functional test fixtures are an essential tool in the defense and military industries. These equipment are used in various fields like those of avionics, engine control, communication, navigational systems and electronic control devices among others. Functional testing is of many types; there is sanity, integration, smoke, regression, user acceptance, interface, and systems testing.

Any failures that may be detected would be caused by problems of interaction amidst the components. Therefore, at this point, testing sets board variants like limiters or timers to their correct settings.

♦ Functional test fixtures are used for several purposes such as;

• To guarantee the product’s quality.

• To establish that everything is suitable and working together with all other components.

• Detect any problems associated with the assemblage of a component or even their individual parts.

• Validate that a product is liberated from any faults that would impact negatively on the usefulness of a product.

Functional testing brings about several merits like; ensuring that necessary conditions are met, satisfying the end-user, reducing risks and losses accompanied by the product, quality improvement, guarantee safety and protection of the end product and also ensure that all components of the product are functioning as expected as well as the product itself.

The advantage of using functional test fixtures is that they allow constant repetition of tests since the same setups are used all the time. Another advantage is that the contriver or formulator can be able to separate distinct functions from methods and reprocess them for more tests. Similarly, rather than working with tests that were previously used, the test fixtures compose them into a recognized state at the start.

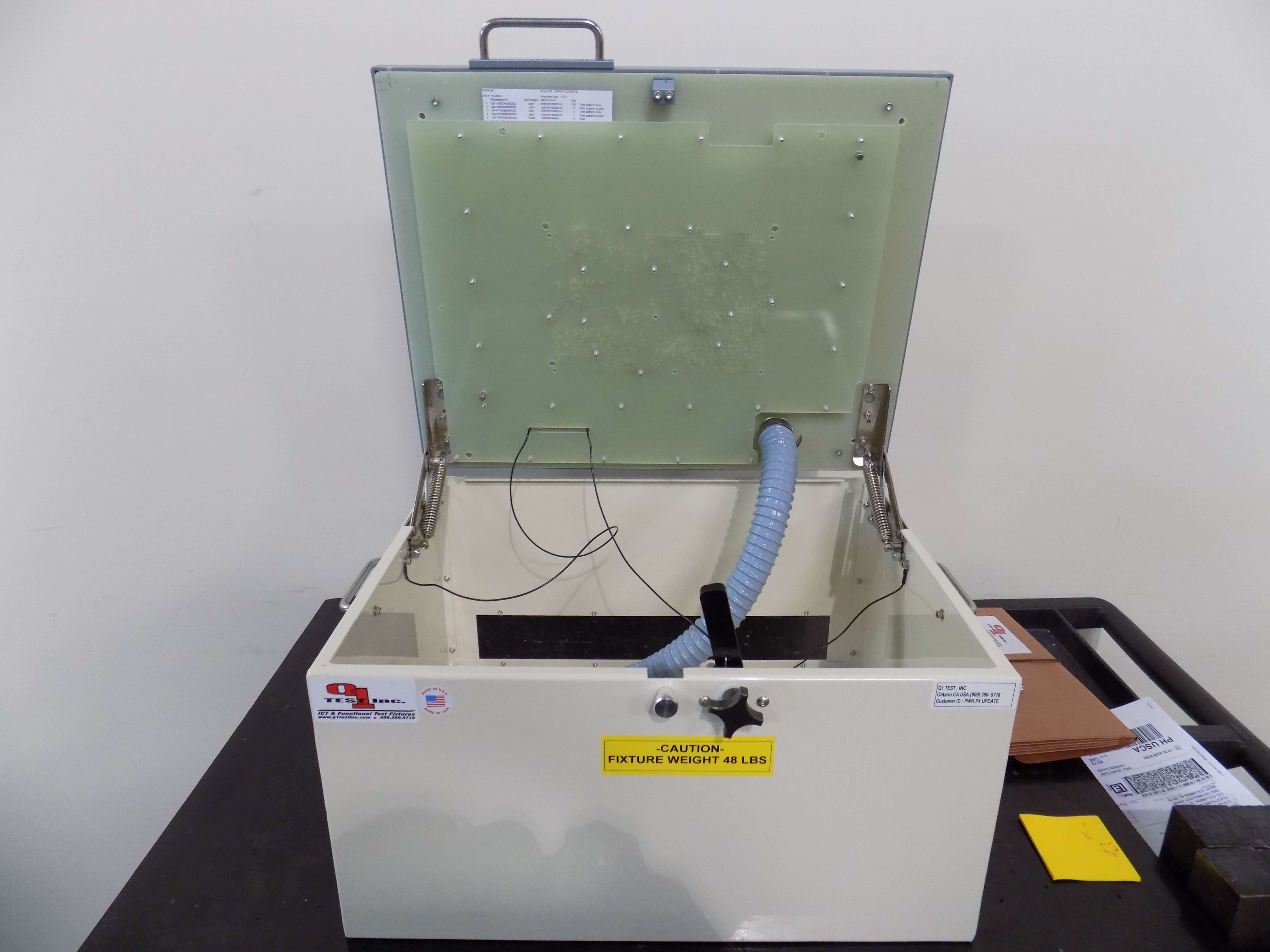

Q1test Inc is a company based in California. Q1 Test Inc is specialized in the production of the functional fixtures. We are highly competent, creative and committed to our work. Our business provides superb services which are satisfactory to the customers. We have very qualitative products that suite the customers’ interests. Our prices for our products are combative, and our dates for delivering the products are authentic and can be relied upon. Above all, we uphold probity or integrity in our business. We have experience from many years of our work to handle even more projects. This is because we have to cope with our changing world and current demands have required us to make advancements in our technology.

OUR QUOTES ARE QUICK AND ACCURATE TO HELP YOU BUDGET YOUR PROJECT.

Contact Us

Q1 Test Inc. fixtures are competitively priced, well built and are made on time. Our quotes are quick and accurate to help you budget your project.

Adress

1100 South Grove Ave, Suite B

Ontario, California 91761

Phone

(909) 390-9718

sales@q1testinc.com