At Q1 Test Incorporated, we understand that every circuit board and electronic device is unique. That is why designing a custom test fixture is not just about connecting wires or probes; it is about creating a solution that ensures your product works perfectly before it leaves the factory.

For many of our clients, the process of taking a test fixture from concept to reality may seem complicated. In this guide, we break it down into simple, clear steps. Whether you are new to electronics manufacturing or exploring test manufacturing solutions for the first time, this guide will help you understand how we approach the design and building of custom fixtures.

Step 1: Understanding Your Product Needs

Every project at Q1 Test Inc. begins with a deep dive into your product. We work closely with you to understand:

- The type of board or device to be tested

- Functional requirements and critical test points

- Production volume and expected throughput

- Any unique physical or electrical constraints

- The type of board or device to be tested

By understanding these factors, our team of test fixture manufacturers ensures that your solution is tailored to your exact requirements.

Step 2: Conceptual Design

Once we gather the specifications, our engineers begin developing the conceptual design. At this stage, we focus on:

- Placement and alignment of the board for accurate testing

- Access to circuit board testers and test device interfaces

- Integration with existing test fixtures or automated test systems

- Safety and reliability considerations

- Placement and alignment of the board for accurate testing

Our goal is to create a design that is both functional and flexible. The conceptual phase allows us to explore multiple approaches and determine the best solution for your product.

Step 3: Prototype Development

After the concept is approved, we move on to prototyping. This step turns ideas into a physical test fixture. We build prototypes that:

- Fit your specific boards and connectors

- Include proper alignment guides and probe placements

- Connect seamlessly with circuit board testers or other equipment

- Fit your specific boards and connectors

At Q1 Test Incorporated, we test every prototype rigorously to ensure it performs as expected. This helps us catch any potential issues before the fixture is finalized for production.

Step 4: Iterative Testing and Refinement

No design is perfect on the first try. Our team conducts iterative testing on the prototype to verify:

- Accurate contact with all test points

- Proper electrical connections

- Compatibility with your existing test process

- Accurate contact with all test points

Feedback from this phase is critical. It allows us to make adjustments, improve durability, and optimize the fixture for speed and efficiency. This iterative approach ensures your fixture is not just functional, but also reliable and easy to use.

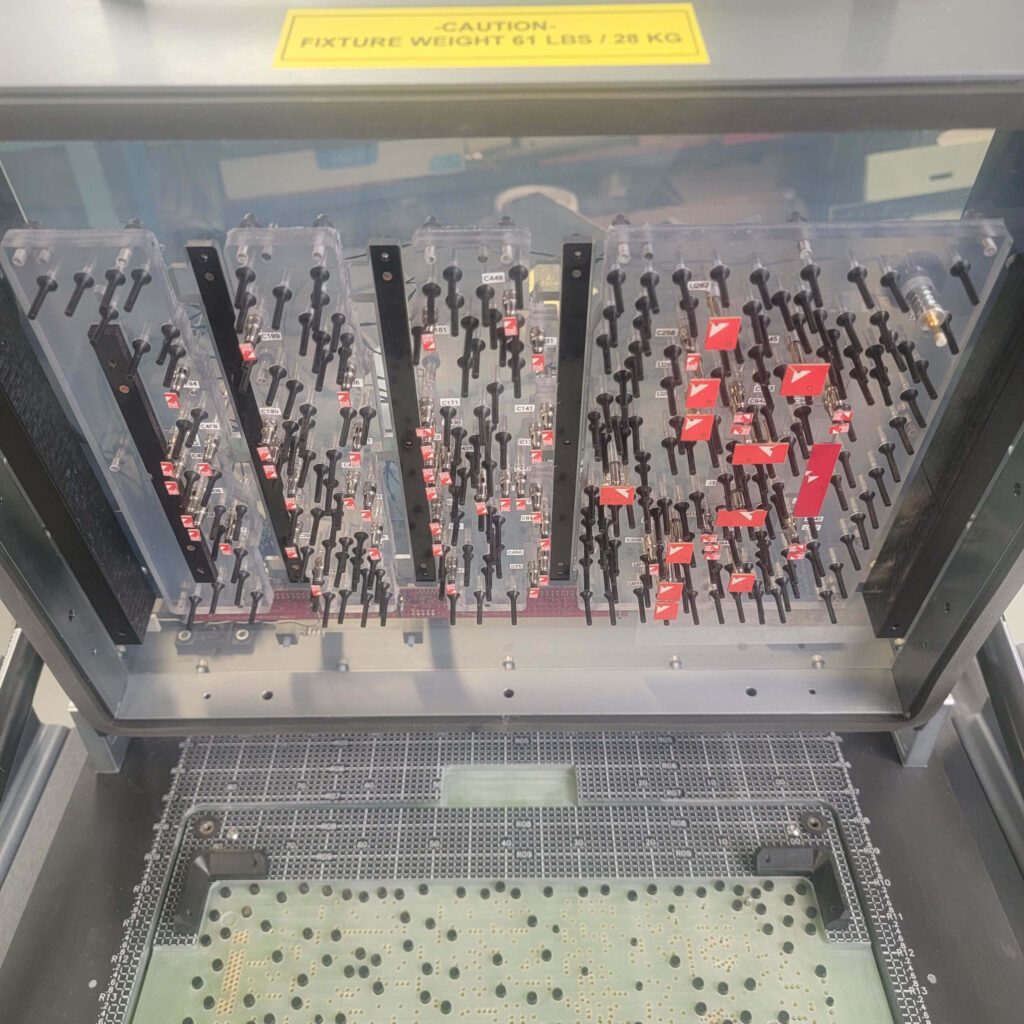

Step 5: Manufacturing the Custom Test Fixture

Once the prototype is finalized, we move to full-scale manufacturing. Our test manufacturing process includes:

- Precision machining for mechanical components

- High-quality wiring and electrical connections

- Integration with automated systems, if required

- Thorough quality checks at every stage

- Precision machining for mechanical components

At Q1 Test Inc., we maintain strict standards to ensure that every test fixture leaving our facility meets your specifications and industry best practices.

Step 6: Delivery, Training, and Support

A custom fixture is only as valuable as its usability. After delivery, we provide guidance and support to ensure your team can use the fixture effectively. This includes:

- Instructions for proper setup and operation

- Recommendations for integration with test devices

- Ongoing support for any maintenance or adjustments

- Instructions for proper setup and operation

We aim to build fixtures that continue to deliver value throughout your production lifecycle.

Why Choose Q1 Test Incorporated as Your Test Fixture Manufacturer?

- Experience with diverse industries: We design fixtures for consumer electronics, medical devices, aerospace, and industrial systems.

- Custom solutions: Every fixture is built to meet your specific product and production requirements.

- Quality and reliability: Our iterative design, prototyping, and testing process ensures accuracy and durability.

- Full-service support: From design to manufacturing and beyond, we stand by your project.

- Experience with diverse industries: We design fixtures for consumer electronics, medical devices, aerospace, and industrial systems.

Choosing the right test fixture manufacturer can make a significant difference in production efficiency, product quality, and overall reliability.

Final Thoughts

A custom test fixture is much more than a set of connectors and probes. It is a carefully engineered solution that ensures your electronic products function as designed. At Q1 Test Incorporated, we guide every project from concept to the factory floor, combining expertise, innovation, and quality craftsmanship.

By investing in a custom fixture, you protect your brand, reduce rework, and ensure that every board leaving your line meets the highest standards.