When you are building electronic products, one thing matters more than anything else: every device must work exactly as intended before it reaches your customer. This is where test fixtures play an important role.

If you are new to electronics manufacturing, the concept of testing equipment might sound too technical. Do not worry. This guide breaks everything down in a simple and friendly way so you can understand what test fixtures are, why they matter, and how they help your business avoid mistakes, defects, and unnecessary costs.

Understanding the Basics: What Are Test Fixtures?

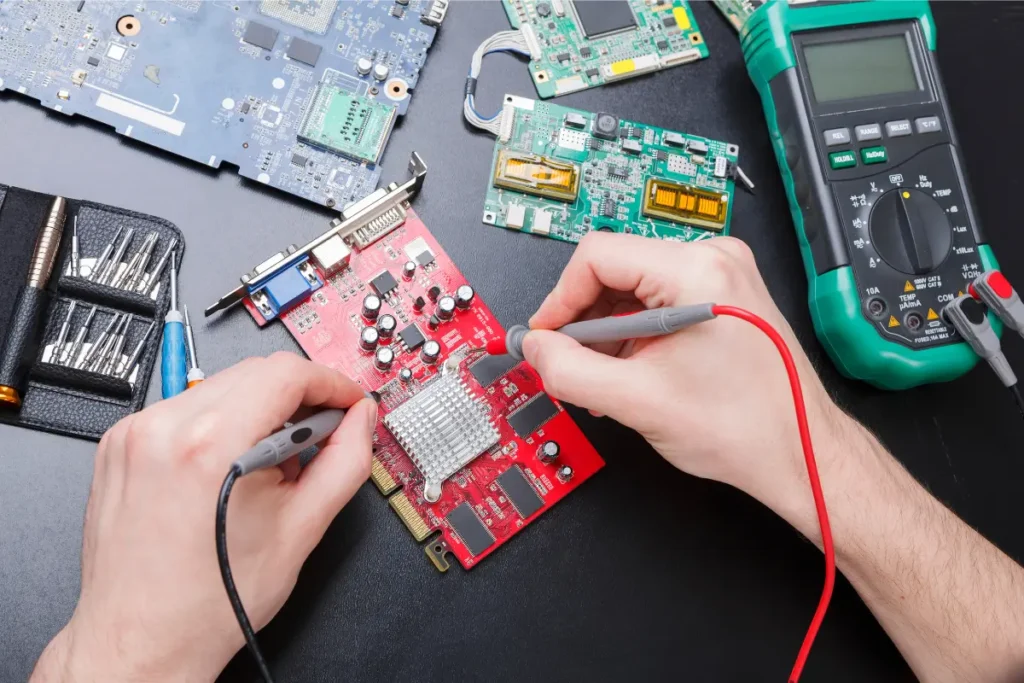

Test fixtures are tools used to check whether a Printed Circuit Board Assembly (PCBA) works correctly. You can think of a test fixture as the station where your circuit boards go to be inspected before they are approved for use.

A test fixture connects your board to automated test equipment or other electrical test equipment. This connection allows the system to measure performance, test components, and confirm that everything is functioning properly.

In short, a test fixture ensures that your circuit board works as expected.

Why Do Manufacturers Use Test Fixtures?

Even a small defect inside a circuit board can lead to a larger issue later. Failures can be expensive to fix, cause customer complaints, and damage your brand. Using test fixtures helps prevent these problems.

Here are the main benefits.

Detects defects early

You can catch issues like missing components, short circuits, or open circuits before the product reaches assembly.

Improves product reliability

You get clear, measurable data showing that your PCBA is performing properly.

Speeds up the inspection process

Test fixtures paired with automated test equipment can inspect hundreds or even thousands of units efficiently.

Reduces rework and wasted materials

A fixture flags defective boards right away, so you do not spend time and resources on products that will not pass final testing.

What Do Test Fixtures Actually Test?

Test fixtures are used to evaluate several important aspects of your PCBA. These include:

1. Electrical continuity

The fixture probes your circuit board test points to confirm that all electrical connections are correct.

2. Component presence and value

It checks if components are installed correctly and if they meet the expected ratings.

3. Functional behavior

Functional fixtures test how the entire circuit behaves when powered on.

4. Safety and reliability

They can verify insulation, grounding, resistance, and other safety-related factors.

This helps ensure your product works reliably once it leaves your facility.

Types of Test Fixtures You Should Know About

There are several types of test fixtures used by electronics manufacturers. Understanding these options helps you decide what your product needs.

1. In Circuit Test Fixtures (ICT Fixtures)

ICT fixtures test individual components and electrical paths. They use probes that touch many circuit board test points to check continuity, resistance, capacitance, and more.

ICT fixtures are great when you want to confirm that the foundation of your circuit board is healthy.

2. Functional Test Fixtures

Functional test fixtures work with automated test equipment to evaluate how the PCBA behaves when it is powered on. Instead of checking components one by one, functional testers check whether the board performs its intended tasks.

This includes testing power behavior, communication ports, user inputs, analog signals, sensors, and other real world functions.

3. Custom Test Fixtures

Some boards have unique shapes, special connectors, or advanced testing requirements. In these cases, manufacturers use custom test fixtures that are built specifically for the product.

These fixtures can include mechanical clamps, special interfaces, automation features, or other custom tools.

How a Test Fixture Works: A Simple Breakdown

The process might look technical but the steps are very straightforward.

Step 1: Place the PCBA in the fixture

The board is set inside a slot designed to align it correctly.

Step 2: Probes make contact

Pins or connectors touch the board’s test points and interfaces.

Step 3: The equipment runs tests

Signals are sent through the board using electrical test equipment or automated systems.

Step 4: Results are recorded

Software displays the pass or fail status and points out any problem areas.

Step 5: Quality control decides the next step

Boards that pass move forward in production. Boards that fail get flagged for rework.

This consistent and repeatable process helps maintain quality in every batch you produce.

Who Uses Test Fixtures?

Test fixtures are essential in industries that rely on electronics. They are commonly used in:

- Consumer electronics

- Automotive electronics

- Medical devices

- Aerospace and industrial systems

- IoT devices

- Robotics and automation

- Consumer electronics

If your product contains a circuit board, you will most likely need a fixture to test it.

Why Test Fixtures Matter for Your Business

Skipping proper testing may seem like a shortcut, but it almost always leads to more expensive problems later. A failed board that reaches a customer can result in:

- Warranty claims

- Product recalls

- Delayed shipments

- Customer dissatisfaction

- Expensive troubleshooting

- Loss of trust

A test fixture helps you avoid these risks by ensuring every board is reliable before it leaves your facility.

How to Choose the Right Test Fixture

If you are just starting out, here are a few key questions to guide your decision.

Identify what needs to be tested

Do you need circuit testing, functional testing, or both?

Examine your test points

Your circuit board test points determine what type of fixture you can use.

Consider your production volume

High-volume production often benefits from automated setups.

Work with an experienced provider

A trusted test equipment partner can design a fixture that fits your product and your workflow.

Final Thoughts: Test Fixtures Help You Build Better Products

If you are new to electronics manufacturing, understanding test fixtures is a smart first step. These tools help you verify product quality, prevent defects, and protect your reputation. Whether your board is simple or complex, a proper test fixture gives you accurate results that keep your production line running smoothly.

Reliable testing leads to reliable products, and that is exactly what your customers expect.