At Q1 Test Incorporated, we work with companies across many industries. One of the most common questions we hear from new clients is why test fixtures are so important. Whether you build automotive components, aerospace electronics, consumer devices, or medical equipment, your products rely on accurate circuit performance. Even a small error can lead to major safety issues, warranty claims, or product failures.

This is where the right test fixture plays a critical role. By pairing your fixture with automated test equipment, you gain reliable and repeatable results that protect both your product and your brand.

Why Testing Matters Across All Industries

Every industry has unique demands, but they all share one thing. They require dependable and high-performing electronics. The automotive sector relies on stable electronics for safety systems, dashboards, and sensors. Aerospace manufacturers depend on flawless components because even one faulty circuit board test can cause mission failure. Medical devices must meet strict compliance requirements and undergo extensive testing.

No matter what industry you serve, the foundation of quality begins with verifying every board through proper testing.

The Role of Test Fixtures in Manufacturing

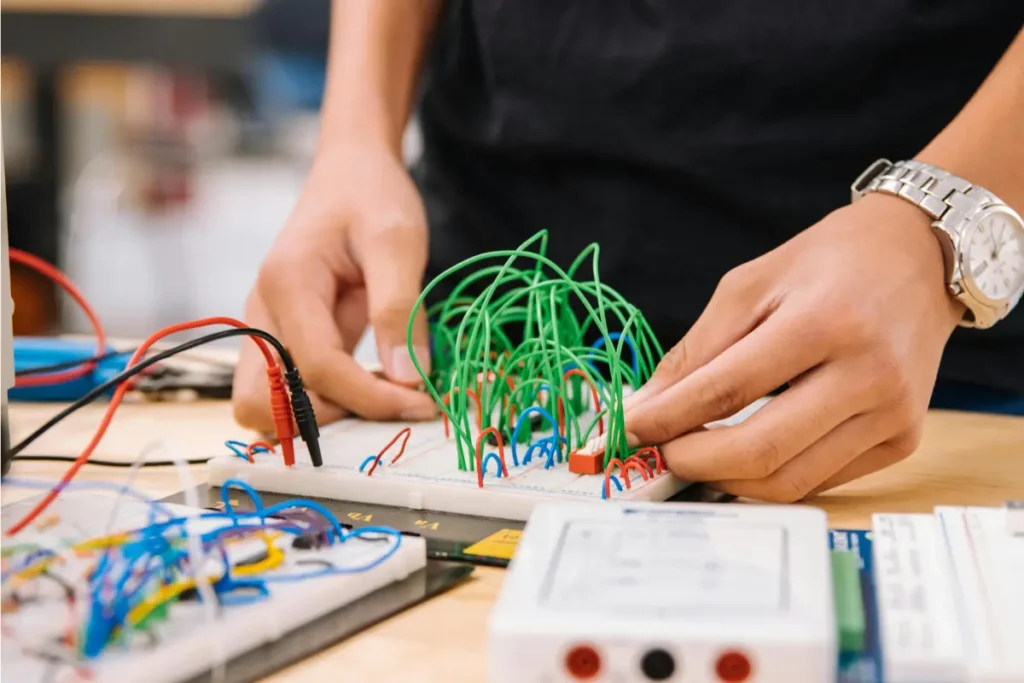

A test fixture is designed to connect a product’s circuit board test points to your testing equipment. This allows every unit to be examined the same way, giving your team consistent results. Fixtures help speed up production, reduce errors, and prevent defects from slipping through.

Automated testing also allows workers to perform checks with less risk of human error. This means electronics get tested faster, more accurately, and with higher repeatability.

Automotive: High Demands for Safety and Reliability

The automotive industry relies on electronic systems that must perform flawlessly in real-world conditions. Sensors, control modules, and power systems are tested using specialized fixtures to ensure accuracy under vibration, heat, and long-term use.

A strong fixture and functional circuit test setup helps catch issues early. This protects manufacturers from recalls and ensures the final product meets industry safety requirements.

Aerospace: Precision Above All

Aerospace electronics must meet strict quality standards. Whether the part is used in a commercial aircraft or a satellite, there is zero room for failure. Fixtures ensure that even the smallest circuit board test is done correctly. Paired with automated test equipment, this reduces risk and enhances system reliability.

Fixtures also help simulate real-world environments so engineers can verify performance under extreme conditions.

Medical: Testing for Compliance and Patient Safety

Medical devices such as diagnostic tools, monitoring systems, and handheld medical electronics require precise testing. Only consistent testing through a high-quality fixture can verify that every part works safely. Medical products undergo both ICT tests and functional tests to ensure they pass regulatory standards.

A strong fixture supports product stability and gives manufacturers confidence that every device is ready for real-world use.

Industrial and Consumer Electronics

Fixtures are just as important in everyday electronics. Consumer devices rely heavily on accurate testing to prevent defects that lead to returns or negative customer experiences. Industrial systems need testing that ensures durability and long-term reliability.

With the help of power circuit testers, in-depth diagnostics and validation become easier and more automated.

How Q1 Test Incorporated Supports These Industries

We design fixtures that support:

- ICT tests

- Functional tests

- High voltage or high current testing

- Fixtures with mechanical actuation

- Fixtures for automated lines

- ICT tests

Our goal is to provide long-lasting solutions that integrate smoothly into your test process.